Hop Modification – S/R-hopping

Modifying the hop is the key to maximising the range an accuracy of any airsoft gun. The hop unit of an airsoft gun works by applying backspin to the bb. The more efficiently the hop setup can apply that backspin the better range and accuracy you can achieve. The conventional hop method is not very efficient:

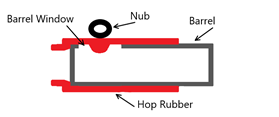

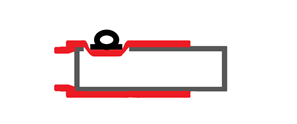

Standard hop rubbers

As you can see the area of hop available (ie. the barrel window) is not being maximised and you will quickly have too much hop rubber protrusion into the barrel, when trying to lift heavy weight bb’s, at which point the hop rubber is unable to apply any more backspin and is simply slowing down the bb and constricting power. This is why standard hop setups can rarely lift heavy ammo, and when it can, power and range are greatly diminished. There is also the issue of the hop rubber having to do two jobs; both air sealing and applying backspin and the same material may not necessarily be optimal for both jobs.

Aftermarket hop rubbers

Newer and better hop rubber designs are now available on the market in all types of different softness and hardness’s. These perform better than a standard rubber simply because they are using more of the available hop area (barrel window) but you still have to use the correct nub to maximise performance. These hop rubber when fitted correctly with the correct nub, softness, etc will give you a noticeable gain in performance over a standard hop rubber. As before there is also the issue of the hop rubber having to do two jobs; both air sealing and applying backspin and the same material may not be optimal for both jobs, hence the need to experiment with different softness to find a happy median.

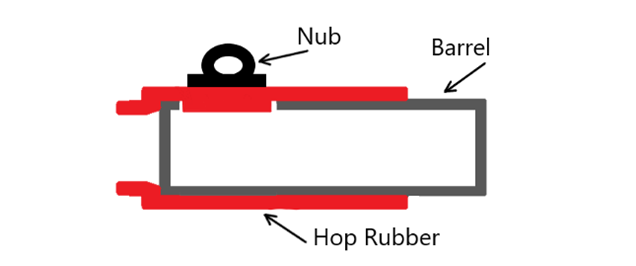

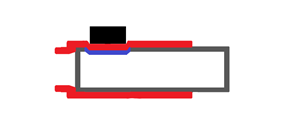

Flat hopping

Flat hopping (not to be confused with S/R-hopping) is where the hop rubber has no internal mound to apply hop:

With this setup you are again making more use of the available hop area, but the issues here are that you are relying on the internal surface of the hop rubber to apply hop which is not always optimal, and the hop rubber needs to be stretched into the barrel to be able to contact the passing bb. Subsequently trying to lift heavy weight bb’s may mean the hop rubber needs to stretch too far causing the rubber to rip and tear against the edges of the barrel window. Once again you are also asking the hop rubber to do both the air sealing and application of hop. With the right hop rubber softness, barrel window and nub combination performance over a standard hop rubber setup will be improved.

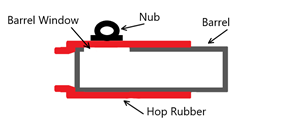

S/R-hopping

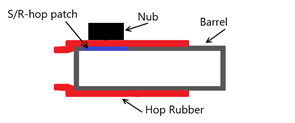

S-hopping and R-hopping are essentially the same, a patch is fitted into the barrel window and when done correctly will give you the best range and accuracy over any other hop setup.

As you can see the hop area is maximised by the hop patch combined with the correct nub, so that backspin is applied to the bb in the most efficient way. Also, air sealing and application of backspin are no longer being done by the same material and can now be done with the optimum materials.

R-hopping is the process of fitting a pre-cut patch into the barrel window. There are many different materials that you can use for the patch. What material you choose, and the internal finish of the fitted patch is very important to maximise performance. The best patch material currently available is the HSA patch.

S-hopping is so called because a Sugru material (mouldable rubber) is used to mould a patch into the barrel window and when set forms part of the barrel meaning the barrel window is now completely sealed. The sugru material, and the internal finish of the hop area that you can achieve with it, means performance can be maximised. At Combat South we S-hop over R-hop due to the process that we have in place which gives performance and durability that can only be equalled with the very best installed R-hop.

So, hop patch material and internal finish of said patch is very important for maximum performance but just as important is the nub that you use. The wrong nub will cause rapid wear and failure of the S/R-hop patch and is the biggest cause of failed DIY S-hop builds. The application of force to said nub is also a factor in producing the best performance results. Direct vertical force is ideal and all upgraded hop setups at Combat South are modified to do this.

A long design and testing process of different nubs, in many difference guns has led to the current nub design which we use. We have been designing and making our own nubs in house for many years now.

Hop setup

Once your hop setup has been upgraded you can now use heavier weight bb’s. We need to use heavy weight bb’s to maximise range and accuracy because an object of greater mass can have more energy imparted into it. This means our heavier bb will fly longer and straighter. For example, all the sniper rifles that we build will have been fitted with our S-hop setup, and with our UK power limit of 2.3J they will be able to lift the heaviest bb’s currently available on the market. Currently we recommend the Geoffs 0.48g Super Precision as the quality, weight and colour are the best available.

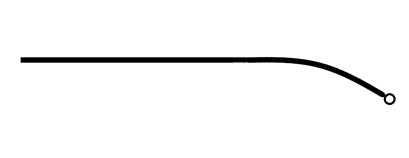

When we setup our S-hopped rifles we always set the hop so that the bb trajectory is straight and dropping of at the end as this maximises accuracy and enables you to confidently elevate to make longer shots:

You can gain more range by apply some over hop which all our S-hopped rifles will happily do, and this can be a usable option, but overall accuracy may be diminished.

If you have any further questions regarding these upgrades you can contact us via email or phone, we are always happy to explain and answer any questions you may have.